Add to Cart

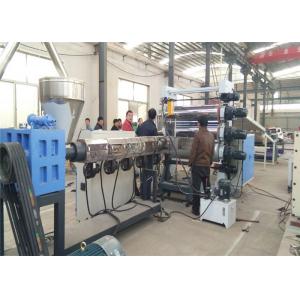

WPC Foam Board Machine , Hot Saled PVC Foam Board Production Line For Furniture Board

Quick detail:

1. kitchen board of PVC WPC foam board making machinery

Macromolecule paint free board:

Compounding material, free from formaldehyde, smooth and beautiful surface, elegant color, paint free, innoxious, gas defence, antihumidity, sound islulation, fire-proof, new kind pf decorative material.

2. Freely foamed board:

Material: PVC

Suitable used place: Used for the decoration, warm keeping and packing such as transportation, construction industry, advertising industry and agricultural etc.

Production parameter:

Model length width thickness

SJ-BC-1200 2400 1220 1-20

SJ-BC-2000 2400 2050 1-20

Description:

1. WPC foam board making machine

WPC foam board making/production/extrusion machine are applied in PVC powde+Wooden powder+other additives raw material to produce kinds of wpc foaming board. Adopting our company's special design and unique processing,

2. These lines can produce different proportion (0.55-0.95) profile wood plastic products to meet customer's needs. With different products, we can match different performance twin extruder or single extruder which equipped with auxiliary devices such as vacuum forming machine, haul-off and cutting machine, loading shelves to optimize its capacity. By using moulds which are specially designed with customer's products, customer can produce the products that they need.

3. The board thickness is easily regulated; mould lips are changeable, so when produce boards of different thickness only to regulate the bolts on mould lips is ok.

Specifications:

| Model | SJSZ-51 | SJSZ-55 | SJSZ-65 | SJSZ-80 | SJSZ-92 |

| Screw dia.(mm) | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

| Max speed(rmp) | 40 | 38 | 38 | 37 | 36 |

| Main motor(kw) | 18.5 | 22 | 37 | 55 | 90 |

| Capacity(kg/h) | 80~100 | 100~150 | 150~250 | 250~380 | 380~700 |

| Center height(mm) | 1050 | 1050 | 1050 | 1050 | 1100 |

| Net weight(kg) | 3000 | 3500 | 4000 | 5500 | 8000 |

| L*W*H(m) | 3.6x1.1x2.1 | 3.6x1.1x2.1 | 4.2x1.5x2.4 | 4.7x1.5x2.4 | 6x1.6x2.5 |

Competitive Advantage:

experience:Our company have more than 15 years’ experience in designing and manufacturing the extrusion equipment; the core technology and equipment are communicating and docking with the advanced European plastics processing technology

Market: Our products have been sold to all over the China and exported to countries all over the world, such as Russia, Ukraine, Armenia, Azerbaijan, Uzbekistan, Kazakhstan, Italy, Romania, Australia, Turkey, Iran, Pakistan, India, Bangladesh, Indonesia, Japan, Vietnam, Mexico, Venezuela, Brazil, Peru, South Africa, Egypt, Tunisia, and so on.